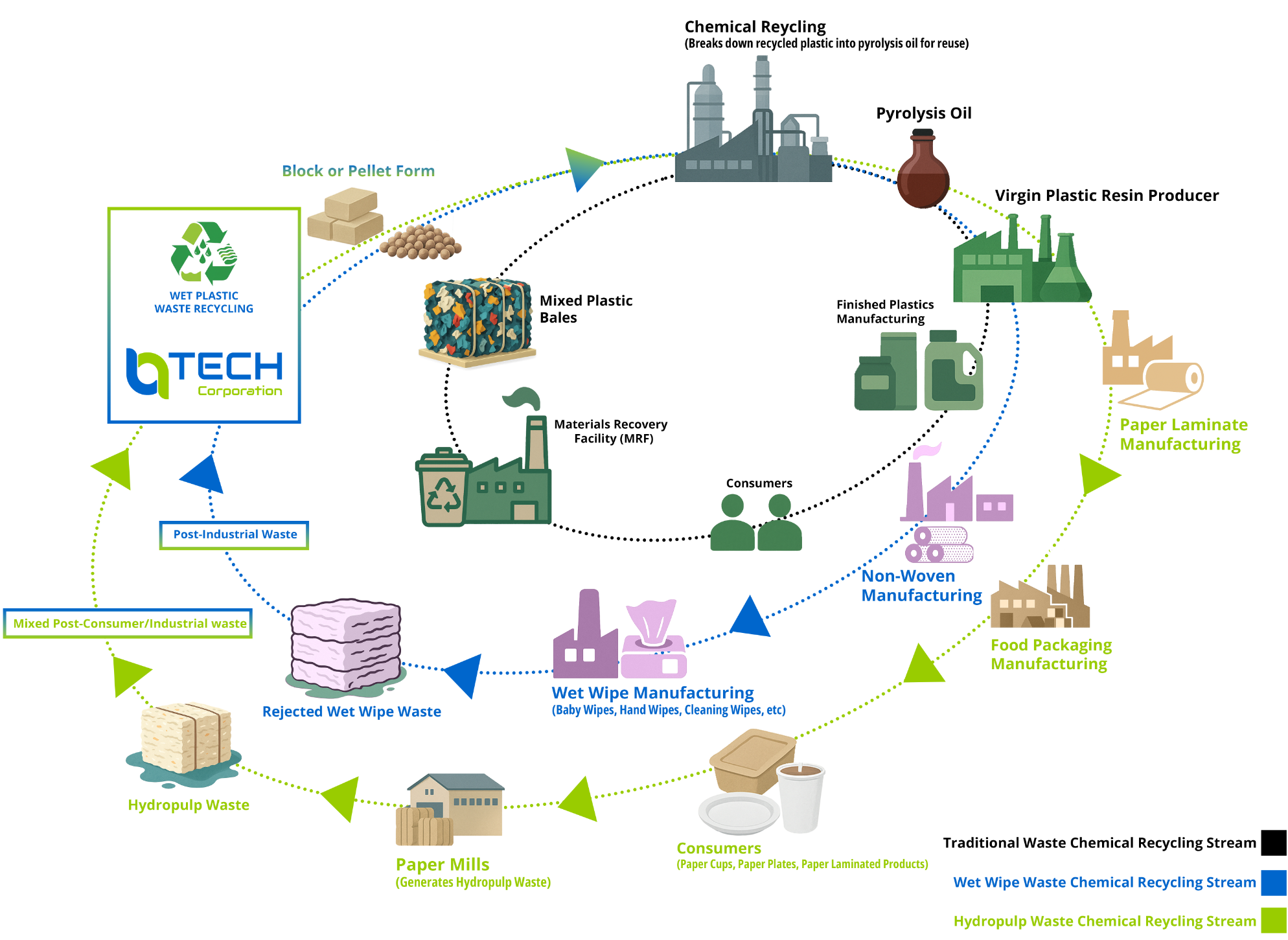

Chemical Recycling

Chemical recycling breaks down plastic waste into its basic chemical building blocks (monomers or other feedstocks) using various processes like depolymerization, pyrolysis, and gasification. Its purpose is to create virgin-quality materials from hard-to-recycle plastics, reducing reliance on new fossil fuels and diverting waste from landfills, thereby supporting a circular economy.

Unlocking New Plastic Waste Streams for Chemical Recycling

- Consistent Plastic Properties: PE & PP (Polyolefin Family)

- Steady Supply of High-Volume Industrial Feedstock

- Landfill-Diverted Material

- Moisture Content Maintained Between 0.05% and 1.0%

BATECH PROUDLY SUPPORTS CIRCULAR RECYCLING THROUGH OUR PROVISION OF CIRCULAR FEEDSTOCKS

Feedstock: Hydropulp Waste

Every year, hundreds of millions of pounds of plastic waste are generated by paper mills. Due to contamination and high moisture content, most of this waste is not recyclable using traditional methods. As a result, it is typically sent to landfills or incinerated. With global demand for disposable paper products on the rise, this environmental challenge is only getting worse.

As demand for single-use paper products grow (post-consumer waste & post-industrial waste), so does the scale of this problem: the global paper packaging market is projected to exceed $630 billion by 2034, and as of 2024, 41 paper mills now accept paper cups for recycling, an increase from 4 paper mills in 2017. This has dramatically increased hydropulp waste generation.

Batech has developed a specialized system to manage this waste stream, transforming it into recycled plastic resin. We currently have access to a substantial amount of hydropulp waste, which provides a significant cost advantage and facilitates the large-scale diversion of plastic waste destined for landfills into a sustainable, circular solution.

Recycling and Sustainability

©Copyright. All rights reserved.